The US consumer market is the largest in the world, making up over 20% of the global FMCG market and 29% of global consumer spending, and is dominated by some of the largest FMCG companies in the world. However, there are a large number of smaller FMCG brands that are growing rapidly, and the large market size of the US consumer market presents a significant opportunity for these brands to capture new pockets of revenue and profits.

These FMCG brands will have to rely on global supply chains to serve this rapidly-growing market, but unfortunately, global supply chains have experienced numerous shocks over the last few years as product shortages and supply-chain disruptions continue to drive headlines. A recent report from Reuters shows that supply chain disruptions may have cost brands up to $4 trillion in lost revenues and caused an average drop of 107% in profitability. Further research shows over the course of the next decade, FMCG brands may face disruptions that could erase half a year’s profits or more. The devastating effects of supply chain disruptions on FMCG brands have forced supply chain leaders to prioritize building resilient, crisis-proof supply chains.

This article will explore the trends that FMCG brands, especially those in emerging markets, need to embrace to make their supply chains more resilient and crisis-proof.

Why are supply chains being disrupted?

The COVID-19 pandemic, rising energy prices, global inflation, and the conflict in Ukraine. These are just a few of many external factors threatening global supply chains today and compounding the troubles in critical sectors. However, contrary to popular opinion, supply chain disruptions did not start recently. Weather disasters, trade disputes, and political instability have long affected the flow of goods and services across nations. These factors are not the problem; they are the symptoms of a much deeper problem – global supply chains are no longer fit for purpose.

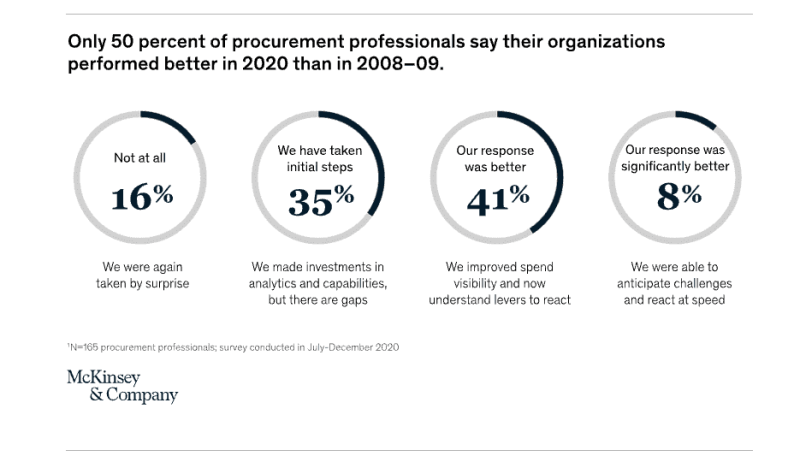

The process of moving raw materials to factories and from factories to merchant’s shelves is broken. For many brands, their supply chains are managed manually, held together by a broken mix of paper and legacy IT, resulting in fragile supply chains that crumble at the first sign of external pressure. Unfortunately, FMCG supply chain managers have not learned from past crises and are still using the same outdated playbook in a fast-changing world. For example, a recent McKinsey survey of supply chain leaders comparing the effect of the pandemic to the global financial crisis of 2008-2009 shows that less than half of the respondents were able to improve their organization’s performance.

The main barrier to improving supply chain resilience is the lack of visibility across the market caused by inefficient distribution processes. The FMCG supply chain still remains relatively inefficient, with smaller retailers still having to order goods via phone calls and SMS, and some brands are still forced to accept and reconcile expensive cash payments. In addition, these brands do not have full visibility across the market and so cannot compete effectively in the competitive American FMCG market.

Digitalization is the only way to increase visibility across the supply chain and make them more resilient. By leveraging digital technologies, especially analytics generated across the supply chain, FMCG companies can spend more intelligently and efficiently and increase speed and transparency while providing decision-makers with crucial insights on where, when, and how to act.

E-commerce is even worse for supply chains.

Supply chain leaders have since recognized the importance of digitalization in building resilient supply chains resistant to disruptions. For example, a 2021 supply chain survey of 71 global companies showed that brands are accelerating their investments in digital technology, with 99% of the respondents admitting a tenfold increase in their digitization efforts from the previous year. However, for many brands, there is still a question of how to integrate digital solutions into their existing supply and distribution processes.

E-commerce and digital selling have long been touted as the future of consumer goods sales, as they could help provide more visibility across the supply chain and make distribution quicker and more efficient. This position seemed to be proved by the rapid e-commerce growth during the pandemic. However, recent data shows that e-commerce revenue is set to shrink for the first time since 2019 caused by supply chain disruptions, showing that e-commerce is not the solution that your supply chains need.

While e-commerce might seem like an improvement over traditional manual distribution chains, two major issues with the model make it unsuitable for solving the problem with supply chains, especially in emerging markets.

- E-commerce eliminates the existing distribution chain: Under the current e-commerce model, third-party online marketplaces like Amazon and Walmart, which account for 95% of all online sales, typically build their delivery networks to replace the existing distribution chain and move goods to the final consumer.

However, as seen already, this model has eliminated millions of retailers and small merchants across the United States. Thousands of mom-and-pop shops are going out of business due to the predatory practices of large tech firms. More importantly, it puts smaller brands and distributors at a severe disadvantage as they lose control of their products and depend solely on e-commerce platforms to distribute them. - E-commerce does not provide brands with supply chain visibility: The primary advantage of digitizing the supply chain is the ability to capture data across the supply chain to provide increased visibility. With the e-commerce model, however, third-party marketplaces like Amazon do not allow brands to access detailed data on where the demand for their products is or who is buying their goods. Instead, the data is captured and used solely by the marketplace to compete, often unfairly, with the brands selling on the platform.

So, what is the solution if e-commerce cannot provide FMCG brands with the needed visibility and supply chain resilience?

Open Commerce is the only way to crisis-proof your supply chain

Smaller FMCG brands in the US need a solution that marries the digital and offline worlds together. This solution must serve the existing fragmented retail market while simultaneously providing real-time data and in-depth visibility across the supply chain. The only solution that can provide this is Open Commerce.

Open Commerce is a revolutionary solution that connects brands, distributors, and retailers on the same digital platform and provides a better way to trade. With Open Commerce, brands can transform their traditional, vulnerable offline supply chains into responsive, resilient chains that can withstand disruption and be rapidly reorganized to maintain maximum efficiency in the face of severe crises.

Build a resilient supply chain with RedCloud’s Open Commerce platform

RedCloud has built the world’s first Open Commerce platform, Red101. It’s an open digital platform connecting the next 1 billion merchants and distributors directly with FMCG brands, allowing them to grow their businesses rapidly.

With Open Commerce, FMCG brands gain visibility across their supply chain and can access granular data from each distributor and retailer in their delivery network in real-time. As a result, for the first time, supply chain managers, FMCG sales, and marketing managers can identify with precision, in real-time, who is buying their products, what quantity they are buying, and where there is excess demand for their products. Armed with this data, they can build more resilient supply chains, reduce product shortages, and maximize growth opportunities in the market.

Schedule a demo today to see how RedCloud can help your brand build a resilient supply chain and reach over 200,000 new retailers across multiple markets.